CHALLENGE:

A southern university required a substantial system upgrade to accommodate plans for campus expansions and future load growth. For years they bought bulk power from the utility grid but now decided they wanted to maintain their own system. Reliability was the main concern, so the university decided to undertake a project which could meet the following requirements:

- Connect radial circuits in closed loops to keep loads from dropping out on fault conditions.

- Switches must be able to isolate faults within 10 cycles.

- Relays must communicate with their source substation and the new SCADA system.

- Feeder cables must accommodate current loads plus future growth.

- Automation must permit the gathering of information to optimize power use.

SOLUTION:

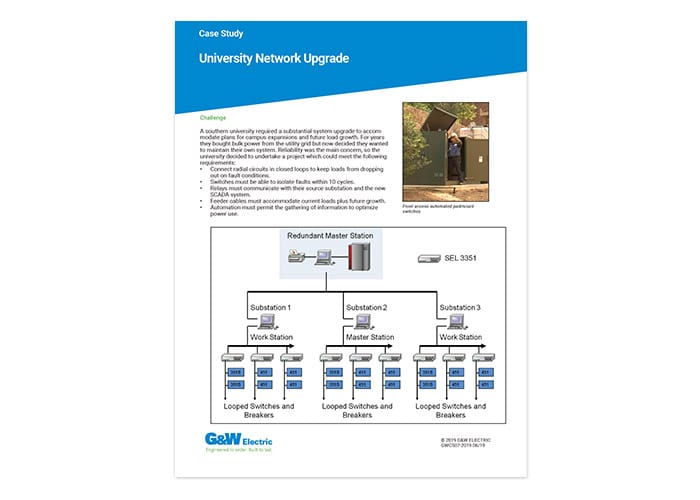

G&W Electric worked closely with the university and the contracted engineering firm to design a Lazer® solution. The new network comprised of ten closed loop circuits with eighteen radial circuits. A total of one hundred ten protective relays were added to new and existing equipment. All retrofit equipment used SEL-351S relays and new equipment used SEL-451 relays.

The communication assisted, closed loop protection system was used to quickly isolate faults without interrupting power to any part of the campus. To do this, the relays were programmed to sense the direction of the fault and communicate to the two adjacent relays using Mirrored Bits protocol. Once the two closest devices determine the location of the fault, they open simultaneously to isolate it without causing interruptions on any of the feeds. Fiber optic cable was used for reliability.

The relays were also monitored through a separate channel by a master station provided by Survalent Technologies. Each switch within a protective loop was connected via DNP protocol to an SEL-3351 processor that was used as a data concentrator. The controls were then tied into two separate local area networks that extended between the substations and to the operations and engineering buildings. Survalent software was used on the local area network and servers to monitor the system and offer central control of all of the devices.

Workstations were located at all of the substations and in the engineering building. The workstations were tied to both networks so personnel could access information about the power system and the individual switches. Two master stations were located at different facilities and also tied into both data networks. This meant that a loss of a master station or a complete communication network would not affect the system because everything was redundant. A Factory Acceptance Test (FAT) was conducted using the actual switches and relays as well as the SCADA software to ensure the system was fully operational before shipping.

CONCLUSION:

The solution was installed in several stages and is operating successfully. Operators have access to real time information and can generate data plots and reports for billing, preventative maintenance, and anticipated load allocations.