BACKGROUND:

When managing high-pressure fluid-filled (HPFF) systems or other high-voltage cable networks, utilities are often faced with aging infrastructure that requires careful maintenance and replacement. While cables themselves can last for longer than a century, their associated terminations typically have a design life of 30–40 years. Replacing these terminations can help extend the operational life of the system significantly—but only if utilities take the necessary precautions to protect the cable during the process.

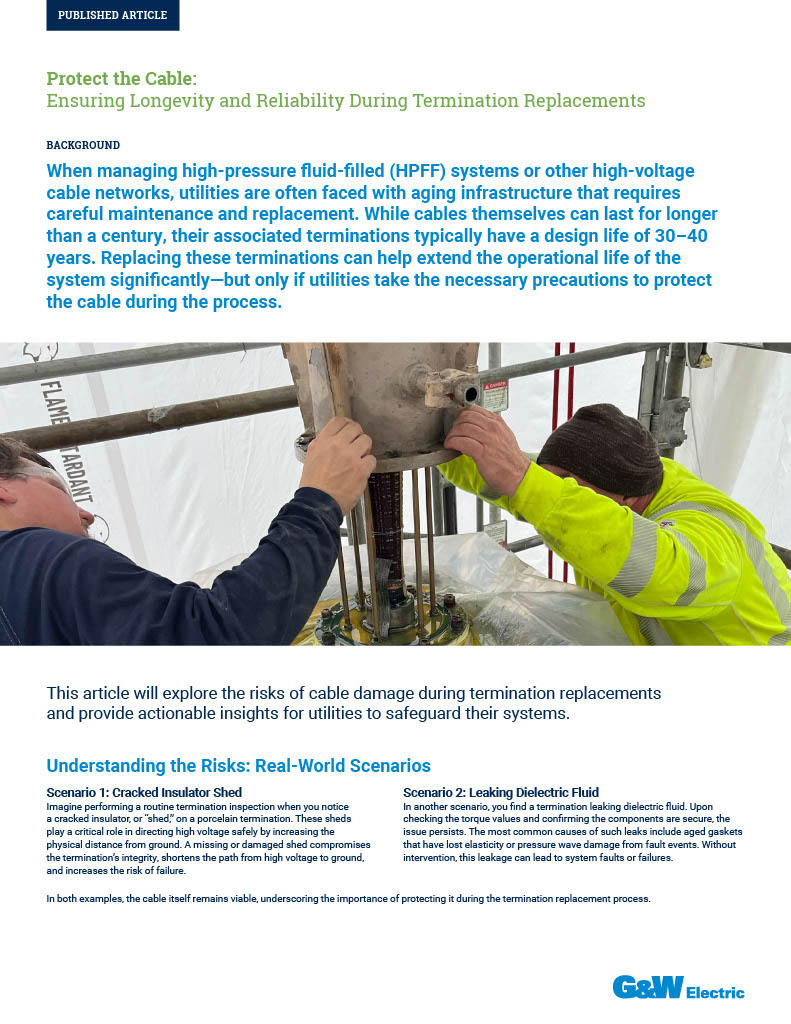

This article will explore the risks of cable damage during termination replacements and provide actionable insights for utilities to safeguard their systems.

Understanding the Risks: Real-World Scenarios

Scenario 1: Cracked Insulator Shed

Imagine performing a routine termination inspection when you notice a cracked insulator, or “shed,” on a porcelain termination. These sheds play a critical role in directing high voltage safely by increasing the

physical distance from ground. A missing or damaged shed compromises the termination’s integrity, shortens the path from high voltage to ground, and increases the risk of failure.

Scenario 2: Leaking Dielectric Fluid

In another scenario, you find a termination leaking dielectric fluid. Upon checking the torque values and confirming the components are secure, the issue persists. The most common causes of such leaks include aged gaskets that have lost elasticity or pressure wave damage from fault events. Without intervention, this leakage can lead to system faults or failures.

In both examples, the cable itself remains viable, underscoring the importance of protecting it during the termination replacement process.

Common Risks During Termination Replacements

When replacing a termination, crews are most likely to encounter the following issues. Luckily, there is a process to address each one successfully.

Cable Slippage

Cable slippage occurs when the cable drops into the pipe during the removal of an old termination. This can lead to misalignment, cable bending, or gaps in the cable’s insulation that reduce the distance to ground. These factors increase the likelihood of faults.

Mitigation

For oil-filled lines, apply a riser pipe freeze using liquid nitrogen to create a plug of frozen dielectric fluid to stabilize the cable.

In both oil- and gas-filled lines, secure the cable by clamping the conductor to prevent movement. Scaffolding or trolley beams can provide additional support during disassembly.

Damage to Previous Preparation

Pre-existing damage from prior installations, overloading, or external events like lightning strikes can compromise the cable. While such damage cannot be undone, further damage during replacement can be minimized with proper precautions.

Mitigation

Ensure all personnel are well-trained and qualified for the task.

Extend the cable beyond the damaged section and rebuild or replace short sections as necessary.

Conduct a thorough assessment of the cable’s condition before starting termination work.

Risks Associated with Pipe Stub Removal

In HPFF systems, removing or modifying pipe stubs can expose cables to potential damage. This may occur during cutting and welding operations, especially if excessive heat is generated, which can transfer to the cable and degrade its insulation.

Mitigation

Use thermocouples to monitor pipe temperature and prevent overheating during cutting or welding.

When feasible, mount new terminations on existing base plates if they remain structurally sound and compatible with the new components.

If the base plate is incompatible, consider using an adapter plate or spool to bridge the gap between different termination designs.

Tools for Adaptation: Plates and Spools

When adapting new terminations to existing base plates, utilities have two primary options:

Adapter Plates: A single plate with bolt circles for both the existing base and the new termination. Suitable when the two mounting patterns do not overlap.

Adapter Spools: Used when bolt circles or sealing surfaces interfere with using an adaptor plate. A spool consists of two plates separated by a short pipe, providing flexibility for complex mounting scenarios. In cases where existing specifications are unknown, blank spools can be shipped for on-site machining. While the field machining approach adds time and complexity, it can be a practical solution when transitioning between manufacturers.

Proactive Maintenance: Preserving System Longevity

Termination replacements are often driven by visible signs of aging, such as leaks, broken sheds, or surface degradation. Utilities that proactively replace terminations can mitigate risks and maintain system integrity without replacing the entire cable.

G&W Electric, a leading provider of cable accessories, including terminations, emphasizes the importance of thorough preparation and high-quality workmanship. By investing in proper training, adopting best practices, and leveraging proven tools, utilities can protect their cables and extend the life of their networks.

CONCLUSION

A Path Forward for Utilities

Termination replacements are a vital aspect of maintaining high-voltage systems. While cables are designed to last a century or more, improper handling during termination replacement can lead to costly repairs, outages, or system failures. By understanding the risks and adopting the mitigation techniques outlined here, utilities can safeguard their investments and ensure reliable service for decades to come.

G&W Electric is committed to supporting utilities via innovative solutions, expert guidance, and quality products tailored to meet the evolving demands of the industry. Working together, we can protect the cable—and the ensure a long, productive future for your power systems.