When a utility serving more than 3.5 million customers across multiple service areas, was tasked with meeting company goals to improve power reliability and upgrade outdated equipment on their transmission network, they reached out to G&W Electric. They needed a new, innovative solution for 69kV applications that could provide automation capabilities, sectionalize transmission lines, provide overcurrent protection, and contribute to their sustainability goals

G&W Electric already supplied them with Viper®-ST distribution-class reclosers for several applications, and for that voltage rating, the Viper-ST reclosers perfectly fit their needs. The Viper-ST product family offers field-proven reliable performance, is automation-ready and can be remotely operated by the utility’s existing communication networks and desired controller. The Viper-ST includes highaccuracy sensors for remote current and voltage sensing and provides the maintenance-free benefits of a solid dielectric insulated device. However, the maximum system voltage rating available of 38kV for the Viper-ST was insufficient for installation on their transmission network rated up to 72.5kV.

G&W Electric was in the process of designing a high-voltage, subtransmission version of the Viper® recloser to meet the needs of the market and was able to fill the need perfectly for this utility.

The Viper®-HV Recloser is Born

G&W Electric listened closely to the needs of the market and customers to understand their pain points. Collaboration with utilities allowed the Viper-HV recloser to be designed for a wide variety of applications

previously unavailable with pole-mounted equipment at this subtransmission voltage class such as maintenance-free overcurrent protection, automation, and sectionalizing. It also enabled the Viper-HV recloser to provide improved installation, testing, and commissioning of the unit to assist in meeting the utility’s reliability goals. In some cases, the Viper-HV allows the utility to avoid having to add a new substation or may avoid having to expand an existing substation, which is a tremendous benefit in terms of logistics, time, and total cost.

Improved Reliability and Automation-Ready

Much of the utility’s 69kV service area is rural, with more than 1,000 miles of transmission line right-of-way. Outages not only affected more customers, but they took longer to resolve since crews would first have to manually identify the fault location and then travel to the nearest substation to restore power. Historically, sectionalizing these long lines between substations was done with air-insulated load break switches that do not have the capability to interrupt faults and lack the ability to provide important field data.

The Viper-HV recloser enabled the utility to minimize the impact of power outages and realize several important benefits:

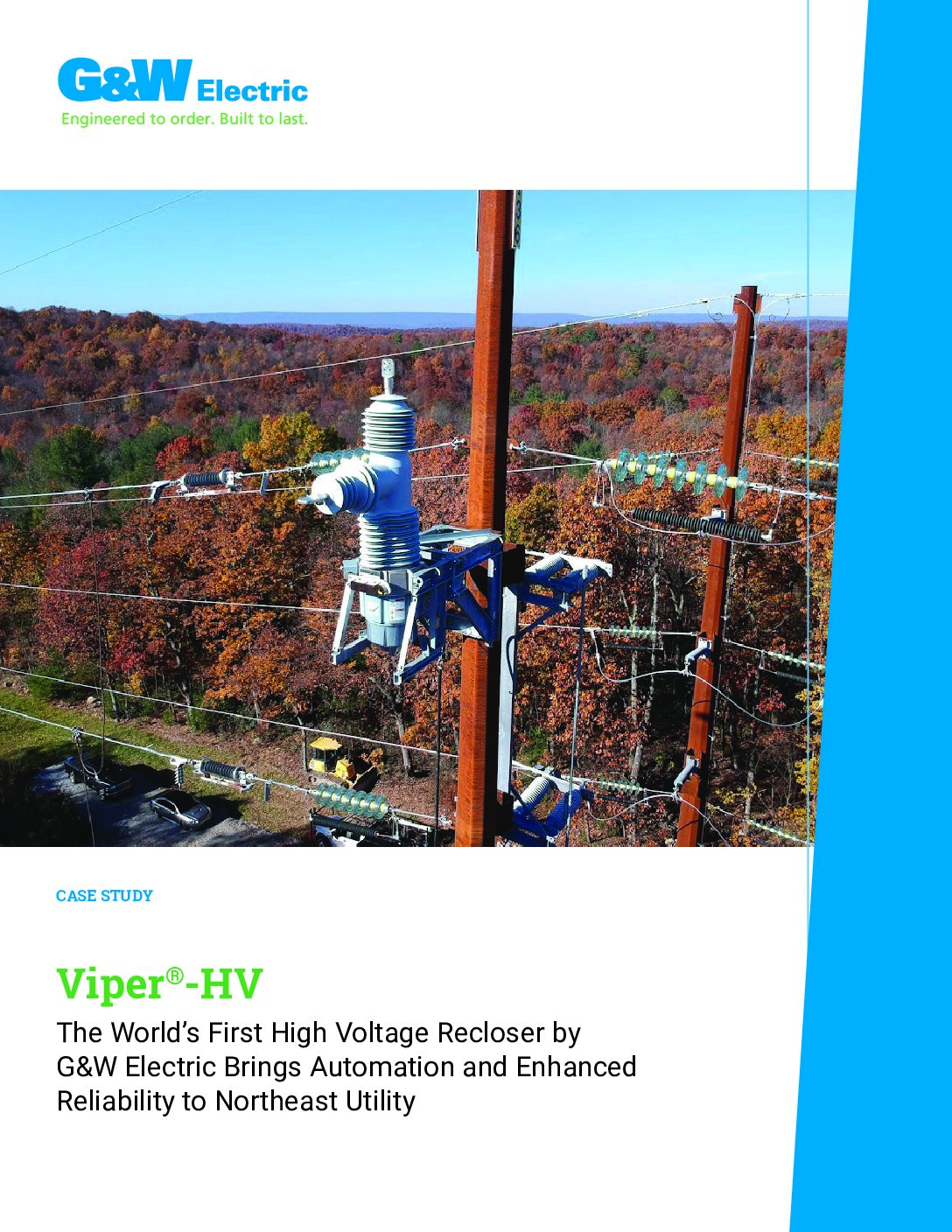

Compact 3-in-1 device: The Viper-HV solution incorporates three separate functions – a recloser, current transformers, and voltage sensors – into a single device, thereby simplifying the installation,

reducing installation errors and saving both cost and time during field deployment.

Minimize customer impact: By sectionalizing the lines and placing one recloser every 2-3 miles along the main sub-transmission line, the utility can significantly reduce the number of customers affected by an outage by isolating the fault to a smaller area.

Intelligent and automation-ready: Integrated, high-accuracy sensors enable the utility to see the status of the sub-transmission lines from virtually anywhere. If an issue does occur, they can easily restore and reconfigure the grid.

Reduced maintenance: Since the Viper-HV is a solid dielectric recloser and doesn’t require oil or SF6 gas, routine maintenance of the interrupter is virtually eliminated, which saves significant time and money.

Improved reliability: A major limitation of the existing solutions was the degradation of key components in the face of harsh weather. With the Viper-HV recloser, all key components are sealed to make them nearly impervious to the elements.

Smaller footprint: Instead of building a new substation, the pole-mounted Viper-HV recloser provides a significantly smaller footprint and initial investment, while still offering similar functionality to other substation protection devices, including current sensing, voltage sensing, remote monitoring and control,

and protection capability.

Easy plug-and-play installation: With a variety of modular and flexible mounting configurations, the Viper-HV recloser is made to fit within the existing overhead infrastructure.

Operator safety: The Viper-HV recloser encapsulates all its internal bus and switching components in solid dielectric insulation. Its construction provides optimum operator safety and protection by reducing exposure to the environment and wildlife.

Sustainability: Supports environmentally significant decarbonization initiatives by eliminating the need for SF6 gas and contributes to achieving net zero carbon emissions.

Investing to Improve Grid Reliability

The successful implementation of the Viper-HV recloser showcased the mutual trust and partnership developed over the years between G&W Electric and the utility. The Viper-HV recloser’s development was based on understanding the specific pain points of the sub-transmission market, and it is available to customers facing similar challenges. The Viper-HV recloser is expected to contribute to improving utilities’ power reliability, enhancing the customer experience, and meeting their reliability and resiliency goals.

What’s Ahead for Power Transmission

Power transmission is critical to society as electricity is a modern necessity. Transmission lines connect power generation companies to the communities in their network to enable our very way of life.

Updating the aging infrastructure of the transmission networks, including modernizing protection and control automation, is key to ensuring reliable service. Updating and adding lines and substations is costly for utilities. Additionally, as more renewable power generation becomes available, these distributed energy resources will have to connect to the grid. As demand increases more power generation is needed, and as more renewable resources fill this need, even more pressure and challenges

are introduced into the aging grid infrastructure.

The recently issued Federal Energy Regulatory Commission (FERC) ruling should reduce the time it takes power generation companies to connect to the grid. This is a major change to FERC’s interconnection requirements. The requests will be grouped into a cluster study to determine what grid updates may be needed. Reducing the interconnection request time from start to completion for power generation companies will improve reliability and reduce the overall cost of the project.

The increase in power generation requires utilities to add technology to monitor the transmission and distribution networks. Automation-ready solutions allow utilities to monitor without increasing staffing.

Utilizing recloser technology, with advanced intelligence in the recloser controllers, on high-voltage transmission lines will increase reliability and reduce costs because the utility doesn’t have to build substations for many use cases. Additionally, these devices can bring automatic reclosing technology, including gas-free technologies in lower transmission voltage classes, to improve transmission grid reliability and resiliency. Coupled with advanced controller applications, such as traveling wave

monitoring, locations of transmission line faults can be very quickly determined to further improve service restoration to large amounts of customers.

Using more capable recloser technology in transmission line sectionalizing also brings value, as it allows standardization and enables fast deployment of equipment to further isolate service outages for minimal negative customer impact, and it enables new protection approaches to be deployed on these higher

voltage lines. Listening to customers who wanted this more advanced similar technology for high-voltage lines, G&W Electric introduced the Viper-HV recloser.