CHALLENGE:

AEP in San Angelo, TX faced challenges when supplying critical power to an industrial plant that produces medical supplies in a sterile environment and operates 24 hours a day, seven days a week. The previous utility setup had been very inconsistent for several years resulting in power outages caused by high winds and wildlife as well as paralleled sources caused by coordination issues with upstream devices. Each outage would cost the plant roughly $100,000 in lost product. This caused AEP Texas to seek another, more reliable solution.

SOLUTION:

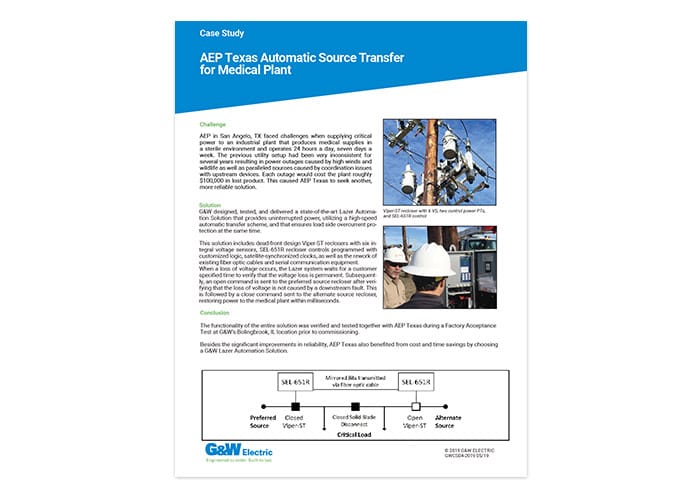

G&W Electric designed, tested, and delivered a state-of-the-art Lazer® Automation Solution that provides uninterrupted power, utilizing a high-speed automatic transfer scheme, and that ensures load side overcurrent protection at the same time.

This solution includes dead-front design Viper®-ST reclosers with six integral voltage sensors, SEL-651R recloser controls programmed with customized logic, satellite-synchronized clocks, as well as the rework of existing fiber optic cables and serial communication equipment. When a loss of voltage occurs, the Lazer system waits for a customer specified time to verify that the voltage loss is permanent. Subsequently, an open command is sent to the preferred source recloser after verifying that the loss of voltage is not caused by a downstream fault. This is followed by a close command sent to the alternate source recloser, restoring power to the medical plant within milliseconds.

CONCLUSION:

The functionality of the entire solution was verified and tested together with AEP Texas during a Factory Acceptance Test at G&W Electric’s Bolingbrook, IL location prior to commissioning.

Besides the significant improvements in reliability, AEP Texas also benefited from cost and time savings by choosing a G&W Electric Lazer Automation Solution.