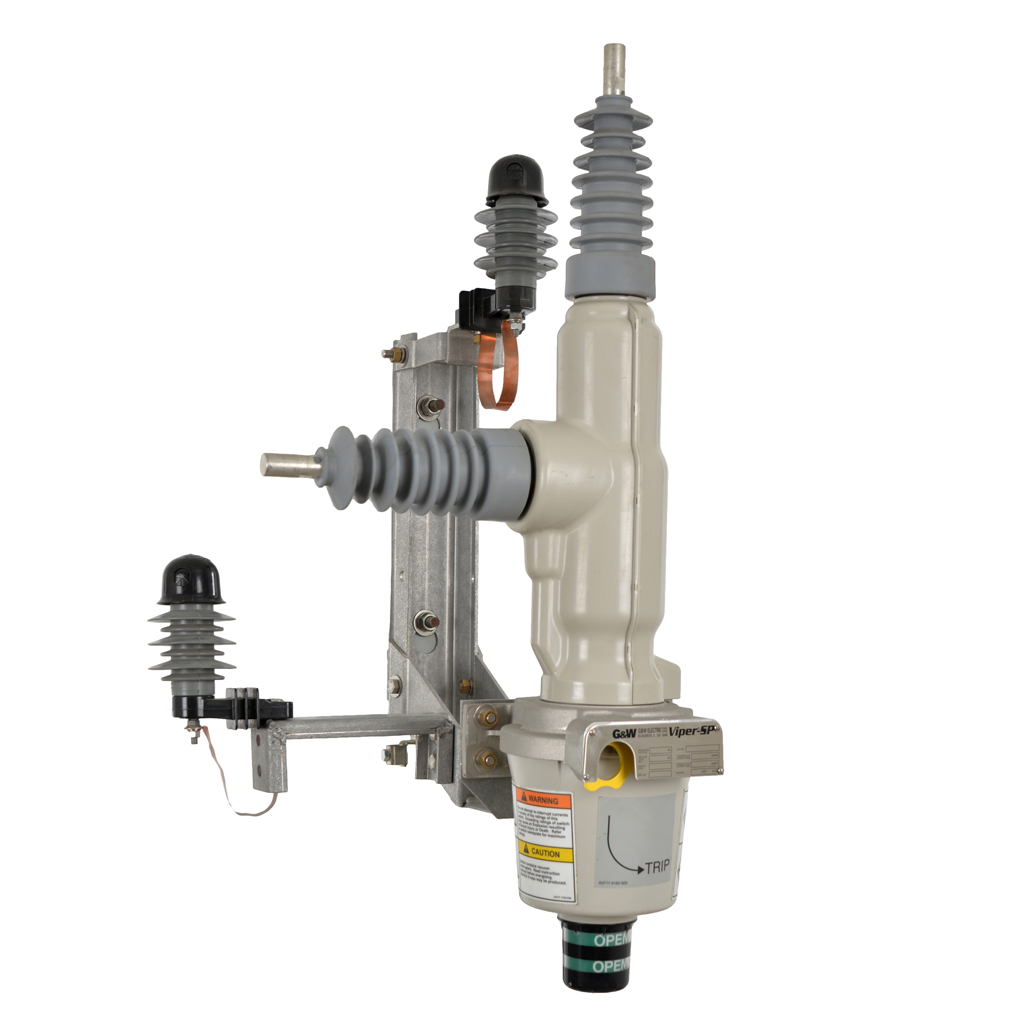

G&W Electric’s Viper®-SP solid dielectric, single phase recloser combines the time-proven reliability of electronically controlled, vacuum fault interrupters with the maintenance-free benefits of a solid dielectric insulated device. The Viper®-SP is designed for automatic or manual operation providing overcurrent protection for single phase systems through 38kV maximum, 800A continuous current, and 12.5kA rms symmetrical interrupting. Vertical insulator “L” configurations and horizontal insulator “Z” configurations are available.

Viper®-SP Single Phase Recloser

Features and Benefits

Reliable Performance Viper®-SP single phase reclosers utilize G&W Electric’s time- proven epoxy polymer system to fully encapsulate the vacuum interrupters. This system provides excellent insulation properties while providing fully shielded, void-free construction.

Ease of Installation The Viper®-SP is lightweight and compact. Site-ready designs provide all accessories including bracket, arresters and voltage transformers.

Ease of Operation The Viper®-SP is compatible with the Schweitzer SEL-351RS Kestrel control.

Power Grid Automation Ready The Viper®-SP is automation ready, simplifying conversion for any future automation requirements.

Configuration Details

- Polemount “L” Bracket

- Polemount Horizontal Insulator Bracket

- Polemount Complete Site-Ready Assembly

Viper-SP Overhead L-Module Configuration

| VOLTAGE | Nominal Frequency (Hz): | 50 / 60 Hz | 50 / 60 Hz | 50 / 60 Hz | 50 / 60 Hz |

| Rated Maximum Voltage (kV RMS) | 15.5 | 27 | 29.3 | 38 | |

| Impulse Level (BIL), kV | 110 | 125 | 150 | 150 | |

| Power-Frequency Voltage Withstand Rating, kV RMS( 60 Seconds Dry) | 50 | 60 | 70 | 70 | |

| Power-Frequency Voltage Withstand Rating, kV RMS( 10 Seconds Wet) | 45 | 50 | 60 | 60 | |

| CURRENT | CT Ratio ṱ | 400/200:1 1000/500:1 | 400/200:1 1000/500:1 | 400/200:1 1000/500:1 | 400/200:1 1000/500:1 |

| CT Accuracy | +/-1% | +/-1% | +/-1% | +/-1% | |

| Continuous Current, A RMS* | 630ṱ / 800 | 630ṱ / 800 | 630ṱ / 800 | 630ṱ / 800 | |

| Short Circuit Interrupting Current, kA Sym, 3 Seconds | 12.5 | 12.5 | 12.5 | 12.5 | |

| Withstand Current (kA, peak) | 32.5 | 32.5 | 32.5 | 32.5 | |

| Line Charging Current (A) | 5 | 5 | 5 | 5 | |

| Cable-Charging Current (100%) A | 25 | 25 | 40 | 40 | |

| First Pole to Clear Factor (kpp) | 1.5 | 1.5 | 1.5 | 1.5 | |

| MECHANICAL | Mechanical Operations | 10,000 | 10,000 | 10,000 | 10,000 |

| Creepage Distance (mm) | 435 | 724 | 955 | 955 | |

| Minimum Phase Spacing (Inches) | 15 | 15 | 15 | 15 | |

| Temperature Range* | -60°C to +65°C -76°F to +150° | -60°C to +65°C -76°F to +150° | -60°C to +65°C -76°F to +150° | -60°C to +65°C -76°F to +150° | |

| NOTE: Power-Frequency Voltage Withstand Rating (Wet) is not applicable for recloser with dead break or elbow connections | |||||

| * 1000A reclosers are rated at 40°C ambient temperature (from 41°C to 65°C rating is 800A) | |||||

| ṱ limited to 630A for 400/200:1 CT ratios | |||||

Viper-SP Overhead Z-Module Configuration

| VOLTAGE | Nominal Frequency (Hz): | 50 / 60 Hz | 50 / 60 Hz | 50 / 60 Hz | 50 / 60 Hz |

| Rated Maximum Voltage (kV RMS) | 15.5 | 27 | 29.3 | 38 | |

| Impulse Level (BIL), kV | 110 | 125 | 150 | 150 | |

| Power-Frequency Voltage Withstand Rating, kV RMS( 60 Seconds Dry) | 50 | 60 | 70 | 70 | |

| Power-Frequency Voltage Withstand Rating, kV RMS( 10 Seconds Wet) | 45 | 50 | 60 | 60 | |

| CURRENT | CT Ratio ṱ | 400/200:1 1000/500:1 | 400/200:1 1000/500:1 | 400/200:1 1000/500:1 | 400/200:1 1000/500:1 |

| CT Accuracy | +/-1% | +/-1% | +/-1% | +/-1% | |

| Continuous Current, A RMS | 630ṱ / 800 | 630ṱ / 800 | 630ṱ / 800 | 630ṱ / 800 | |

| Short Circuit Interrupting Current, kA Sym, 3 Seconds | 12.5 | 12.5 | 12.5 | 12.5 | |

| Withstand Current (kA, peak) | 32.5 | 32.5 | 32.5 | 32.5 | |

| Line Charging Current (A) | 5 | 5 | 5 | 5 | |

| Cable-Charging Current (100%) A | 25 | 25 | 40 | 40 | |

| First Pole to Clear Factor (kpp) | 1.5 | 1.5 | 1.5 | 1.5 | |

| MECHANICAL | Mechanical Operations | 10,000 | 10,000 | 10,000 | 10,000 |

| Creepage Distance (mm) | 435 | 724 | 955 | 955 | |

| Minimum Phase Spacing (Inches) | 15 | 15 | 15 | 15 | |

| Temperature Range | -60°C to +65°C -76°F to +150° | -60°C to +65°C -76°F to +150° | -60°C to +65°C -76°F to +150° | -60°C to +65°C -76°F to +150° | |

| NOTE: Power-Frequency Voltage Withstand Rating (Wet) is not applicable for recloser with dead break or elbow connections | |||||

| ṱ limited to 630A for 400/200:1 CT ratios | |||||

Viper-SP Padmount Z-Module or C-Module Configuration

| VOLTAGE | Nominal Frequency (Hz): | 50 / 60 Hz | 50 / 60 Hz | 50 / 60 Hz | 50 / 60 Hz |

| Rated Maximum Voltage (kV RMS) | 15.5 | 27 | 29.3 | 38 | |

| Impulse Level (BIL), kV | 110 | 125 | 125 | 150 | |

| Power-Frequency Voltage Withstand Rating, kV RMS( 60 Seconds Dry) | 35 | 40 | 40 | 50 | |

| DC Withstand (15 Minutes) | 53 | 78 | 78 | 103 | |

| CURRENT | CT Ratio ṱ | 400/200:1 1000/500:1 | 400/200:1 1000/500:1 | 400/200:1 1000/500:1 | 400/200:1 1000/500:1 |

| CT Accuracy | +/-1% | +/-1% | +/-1% | +/-1% | |

| Continuous Current, A RMS | 630ṱ / 800 | 630ṱ / 800 | 630ṱ / 800 | 630ṱ / 800 | |

| Short Circuit Interrupting Current, kA Sym, 3 Seconds | 12.5 | 12.5 | 12.5 | 12.5 | |

| Withstand Current (kA, peak) | 32.5 | 32.5 | 32.5 | 32.5 | |

| Line Charging Current (A) | 5 | 5 | 5 | 5 | |

| Cable-Charging Current (100%) A | 25 | 25 | 40 | 40 | |

| First Pole to Clear Factor (kpp) | 1.5 | 1.5 | 1.5 | 1.5 | |

| MECHANICAL | Mechanical Operations | 10,000 | 10,000 | 10,000 | 10,000 |

| 200A Deepwell* | Available | Available | Available | Available | |

| Temperature Range | -60°C to +65°C -76°F to +150° | -60°C to +65°C -76°F to +150° | -60°C to +65°C -76°F to +150° | -60°C to +65°C -76°F to +150° | |

| ṱ limited to 630A for 400/200:1 CT Ratios | |||||

Accessories

For site-ready configurations, the Viper-SP can be provided with:

Lightning Arresters:

Lightning Arresters are not installed, they can come with their primary wires connected to the Viper-SP’s terminals and have their ground strap connected.

Control Power Transformer:

Either an oil control power transformer (CPT) or a solid dielectric potential transformer (PT) can be added to the frame of the Viper-SP. The primary connection can be made to the Viper-SP. An AC cable can be provided so it’s either connectorized or hardwired on the control end.

Mounting flexibility:

An orientation bracket can be provided to allow the Viper-SP to be installed facing either away from the pole or with the horizontal insulator on the left or right side to better fit the pole construction.

Fully connectorized control cable:

As default, the Viper-SP comes with the main cable wired into the mechanism for interface with the control. This control cable is only connectorized on the control side. As an available option, the main cable can be connectorized at the recloser mechanism side as well.

Download product brochures, article, white paper and case study: