How G&W Electric Equipment Supports Microgrid Reliability

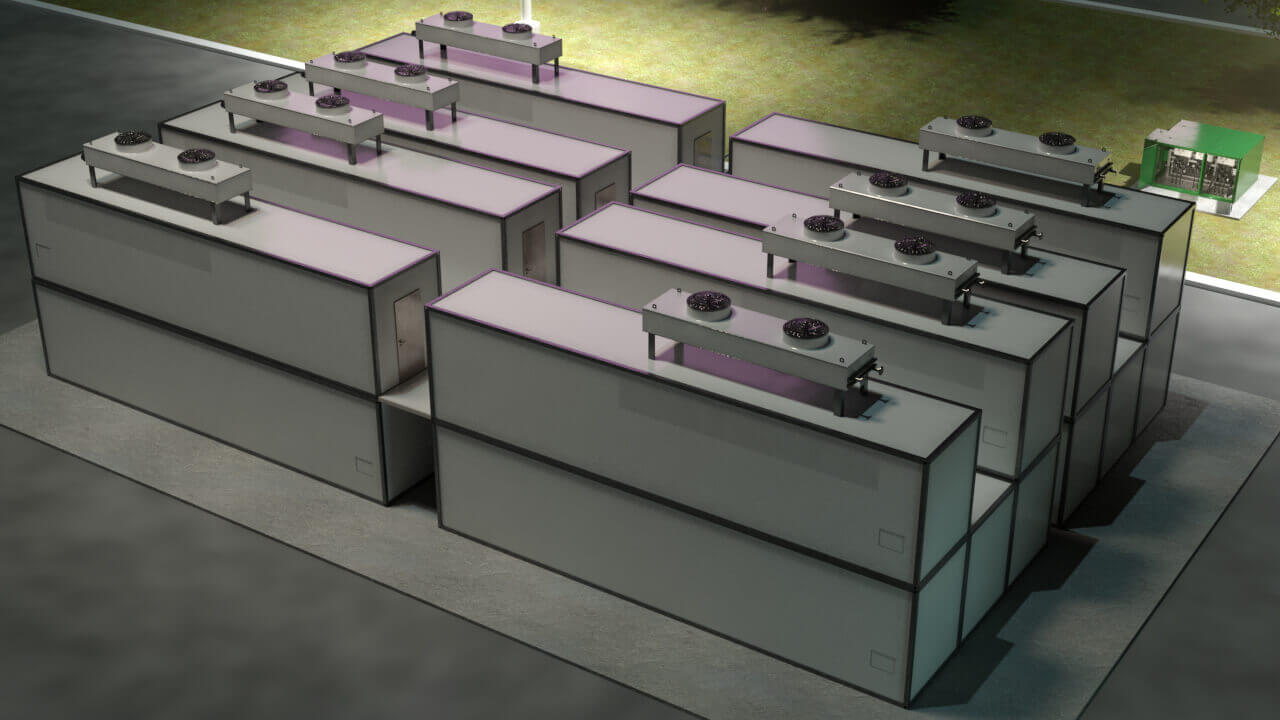

Discover our state-of-the-art microgrid, which showcases how G&W Electric’s reclosers, switchgear, and sensor technologies enhance reliability and resilience. Through advanced automation, the system intelligently manages power generation and energy storage, automatically isolating from the main grid during an outage to maintain uninterrupted operations.

When a severe snowstorm completely shut down our operations, G&W Electric recognized the benefits of installing a microgrid to deliver uninterrupted premium power to support our critical operations as well as our customers.

John Mueller

Chairman and Owner of G&W Electric

Our Microgrid Installation

In service since late 2022, the microgrid has helped prevent costly production disruptions, reduced environmental impact, and provided additional energy that can be returned to the grid. Learn more about the installation process:

Explore the Future of Power with Advanced Microgrid Technology

The G&W Electric microgrid elevates power reliability and resilience at our headquarters by leveraging localized, automated power generation and storage capabilities. During instances of power outages, the microgrid seamlessly isolates or “islands” from the primary power grid to ensure uninterrupted operations.

In addition to ensuring the continuity of operational lighting and uninterrupted production during instances of primary power grid unavailability, a microgrid also serves as a means to reduce carbon footprints, offers an alternative generation source, enhances safety measures, provides community protection, and offers potential cost savings.

Explore our interactive microgrid